Advantages of Using Meniscus Lenses in Infrared Applications

Authors: Katie Walker

Spherical Aberration | Benefits of Meniscus Design

Compared to many other forms of optical lenses, meniscus lenses are rarely offered off-the-shelf. While meniscus lenses are primarily used for focusing to small spot sizes or collimation applications, plano convex lenses often offer a superior price-to performance ratio. There are scenarios, though, where meniscus lenses provide significantly superior performance at only a moderate increase in price.

Spherical Aberration

Due to the spherical nature of a lens, spherical aberrations cause parallel rays at different distances from the optic axis to not converge at the same point (Figure 1). While spherical aberrations can be corrected by using multiple elements that overcorrect other elements, for many IR systems where materials are significantly more costly than visible materials, it is ideal to minimize the number of elements. In lieu of using multiple elements, it is possible to minimize spherical aberration for a single lens by shaping the lens into its best form.

Figure 1: Spherical Aberrations

For a fixed index of refraction and lens thickness, an infinite number of radii combinations exist that can be used to create a particular focal length lens. These combinations of radii create different lens shapes which directly result in spherical aberrations and coma due to the degree in which a ray bends as it travels through the lens.

The lens shape can be described by the Coddington shape factor, C (Equation 1 and Figure 2).

Using the thin lens aberration equations with an object at infinity and the stop at the lens, we can derive the condition for minimum spherical aberration (Equation 2).

Assuming a constant wavelength could be held, relationship between index and shape factor for minimum spherical aberration can be visualized (Figure 3).

Figure 3: Best Form Shape Factor as a Function of Index of Refraction

Benefits of Meniscus Design

When working in the visible, glass indices typically range from 1.5 to 1.7 and the shape for minimum spherical aberration is nearly plano-convex. In the infrared, however, higher index materials like germanium are typically used. Germanium, with its index of 4.0, greatly benefits from a meniscus lens design by significantly reducing spherical aberrations.

The minimum spherical aberration occurs when the ray is bent equally at both interfaces. While the first surface of a germanium meniscus lens causes light to bend slightly more than a comparable PCX lens, the second surface of a PCX lens causes light to bend significantly more, resulting in an overall increase in spherical aberration.

As shown in Figure 4, which compares the performance of a 25 x 25mm germanium PCX lens to a 25 x 25mm germanium meniscus lens, it is easy to see how the PCX lens causes light to bend significantly more with respect to the lens surface than the comparable meniscus lens. This increase in bend causes an increase in spherical aberration. The germanium meniscus lens demonstrates a drastic decrease in resulting spot size, making it more ideal for use in demanding IR applications.

| PCX Lens | Meniscus Lens | |

|---|---|---|

| S1 spherical abberation | 0.1 waves | 2.4 waves |

| S2 spherical abberation | 14.2 waves | 2.9 waves |

| Total spherical abberation | 14.3 waves | 5.3 waves |

| Spot Size | 258μm | 83μm |

Figure 4x: Diagram of 25 x 25mm Germanium PCX Lens versus 25 x 25mm Germanium Meniscus Lens

While meniscus lenses can still provide increased performance in the visible, typically there is not enough gain to offset the added manufacturing costs. Table 1 compares the performance in the visible spectrum of a 25 x 50mm calcium fluoride (CaF2) PCX lens with a comparable meniscus, along with the infrared performance of a 25 x 50mm germanium (Ge) PCX lens with a comparable meniscus lens. The germanium lenses exhibit a significant reduction in spot size when a meniscus shape is used.

| PCX Spot Size | Meniscus Spot Size | Reduction with Meniscus | |

|---|---|---|---|

| Visible (CaF2 Lenses) | 849.3μm | 624.9μm | -26% |

| Infrared (Ge Lenses) | 258μm | 83μm | -68% |

Table 1: Spot Size Comparison of PCX Lenses versus Meniscus Lenses in Visible and Infrared Applications

While a meniscus lens may not provide benefit in all applications, meniscus lenses can offer great cost and performance benefits for many infrared applications, including spectroscopy and thermal imaging.

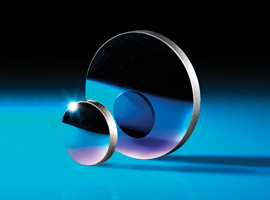

Meniscus Lenses from Edmund Optics®

Edmund Optics® offers a wide range of meniscus lenses spanning the entire range of options discussed above.

Germanium Meniscus Lenses

Germanium Meniscus Lenses

- Superior spherical correction and durable design for demanding applications.

BUY NOW

ISP Optics Germanium (Ge) Meniscus Lenses

- Minimize spherical aberration and reduce spot sizes

BUY NOW

ISP Optics Zinc Selenide (ZnSe) Meniscus Lenses

- CVD Grade Zinc Selenide (ZnSe) Ideal for CO2 Systems

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®