Acktar Advanced Coatings

Authors: Samuel Josephs

Introduction

Acktar is a world leader in light absorbing materials and coatings, that provide solutions for stray light suppression in the UV, VIS, SWIR and MWIR wavelengths.

Available Black Foils and Direct Coated optomechanics are ideal for light trapping applications such as within lens housings, baffles, IR sensors, UV sensors, passive infrared detectors, black bodies, light detectors, UV absorbers, etc. Find our full product lineup here.

In optics and photonics applications, Acktar coatings and foils are able to selectively suppress stray light and significantly increase signal-to-noise ratio, so you get the clearest and most accurate readings and images from your sensors. Acktar coatings and foils also have a high laser damage threshold and can dissipate heat efficiently - perfect for catching a stray laser beam before it can cause damage to you or your system.

Edmund Optics® Offering

Edmund Optics® offers Acktar foils in sizes from 1” diameter stickers, up to 50m long rolls. Acktar foils come in many coating options: Metal Velvet, Lambertian Black, Maxi Black, Spectral Black, and Hexa Black. Each coating type is designed with varying reflective performance, with differing ideal spectral ranges so that there is a coating with is ideal for your application.

We also offer direct coated optomechanics products, such as optical pinholes and optical slits for spatial filtering, Hexa-Black coated C-Mount tubes for noise reduction, as well as beam dumps to safely control the beam in your laser system.

Acktar Performance Data

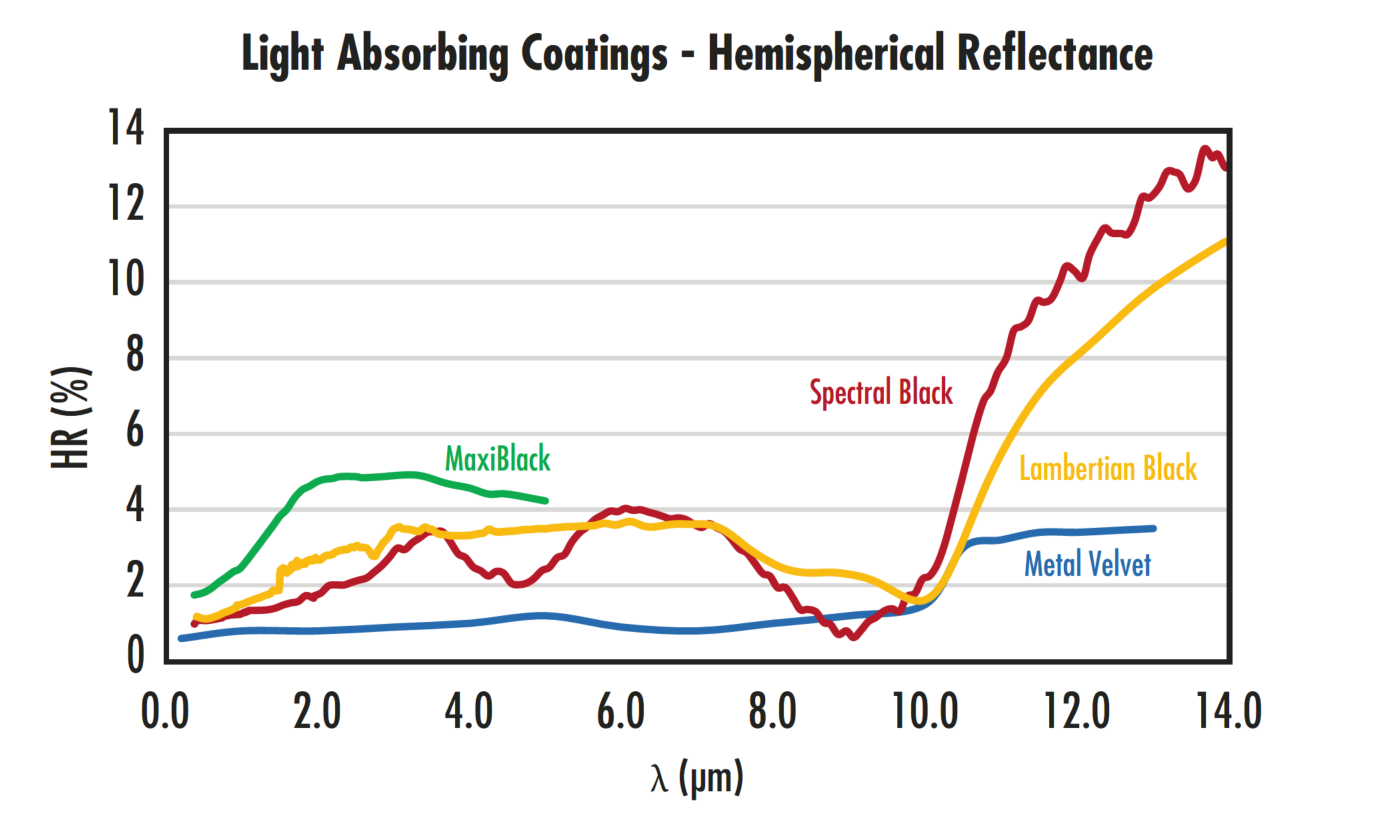

Different Acktar Black Coatings are better suited to specific optical applications depending on the design wavelength of the system or application.

Figure 1: Hemispherical Reflectance of Acktar Black Coatings at Specific Wavelengths

It is also important to understand the typical angle of incidence of the system and the abrasive resistance required for the application when selecting the ideal black coating for the application. Please reference the table below that compares the different types of Acktar Black Coatings.

| Foil Type | Metal Velvet™ Extra Diffusive  |

Lambertian Black™Ultra Diffusive  |

MaxiBlack™Diffusive Polyimide  |

Spectral Black™Semi-Specular  |

Hexa Black™Semi-Specular  |

|---|---|---|---|---|---|

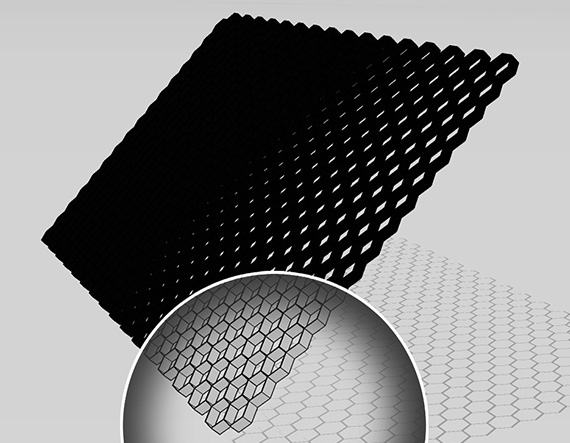

| Substrate Material | Aluminum | Stainless Steel | Polyimide (Kapton) | Aluminum | Aluminum Honeycomb |

| KEY FEATURE | Reflectance -1% | High Absorptance at Grazing Angles | Thin Polyimide | Semi Specular Finish | Ultra-high Absorptance at Grazing Angles |

| Thickness | 120µm | 100µm | 25/50/75µm | 130µm | 2mm |

| Appearence | Diffusive | Highly Diffusive | Diffusive | Specular | Diffusive 3D Structure |

| Typical Spectral Range | EUV-FIR | EUV-FIR | UV-MWIR | VIS-MWIR | EUV-FIR |

| AOI Range | 0-60° | 0-80° | 0-60° | 0-45° | 0-88° |

| Reflectance normal AOI | <1% | <1.5% | <2.5% | <2% | <1.5% |

| Abrasion Resistance | Light | Moderate to high | Moderate | Moderate | Moderate plus |

| Self adhesive back | Self adhesive back standard - available without adhesive | ||||

| Service Temperature | |||||

| Without Adhesive: Long term (-)196°C to (+)350°C; short term up to (+)400°C | (-)258°C to (+)250°C | ||||

| With Standard Adhesive: Long term (-)40°C to (+)121°C; short term up to (+)177°C | |||||

| With Low-Outgassing: Long term (-)50°C to (+)150°C; short term up to (+)260°C | |||||

Figure 2: Comparison of Acktar Black foils types.

| Metal Velvet™ / Spectral Black™ |

Commercial Flock Paper | Black Anodized Foil | |

|---|---|---|---|

| Materials Content | Completely Inorganic | Organic/Fibers | Non Organic Basis + Pigments |

| Ultra High Vacuum | Compatible | Probably Incompatible - Outgassing | Compatible |

| Laser Damage Threshold | Very High | Low | Low |

| UV Tolerance | Very High | Low | Low |

| Particulation | Metal Velvet™ - Minimal Spectral Black™ - None |

Particulates | None |

| Thermal Conductivity | High | Low | Low |

| Electrical Conductivity | Conductive | Non-conductive | Low |

| Operating Temperature, Adhesive Limited [C] | -40 to 180 | No Data | ~150 |

| Fluoresence | None | High | High |

Figure 3: Comparison of Light Blocking Performance of Acktar Metal Velvet and Spectral Black vs. Flock Paper and Black Anodization.

| Spectrum | WL [NM] | ||||

|---|---|---|---|---|---|

| Metal Velvet™ | Spectral Black™ | Flock Paper | Anodized Foil | ||

| R [%] | R [%] | R [%] | R [%] | ||

| UV | 190-405 | 1 | 1 | Limited Use | Limited Use |

| VIS | 400-780 | 1 | 1.5 | 3.5 | 5 |

| NIR-SWIR | 800-1700 | 1.2 | 2 | >25 | >20 |

| MSWIR | 3000-5000 | 2 | 3 | >15 | 17 |

| LWIR | 8000-11000 | 4 | 7 | 5 | 5 |

- R[%] refer to peak reflection value in the WL range

- Black anodized / Flock are typical data

Figure 4: Reflection Performance of Acktar Black Coatings at Specific Wavelength Bands.

VISIBLE

VISIBLE NIR

NIRFigure 5: Visual Comparison of Light Blocking Performance of Acktar Black Coatings in IR vs Conventional Black Coating.

Find our full offering of standard Acktar Foils and Direct Coated Optomechanics here. If you have a demanding application, please feel free to reach out to us for custom sizes or substrates.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act