Manual Stages and Slides | View All

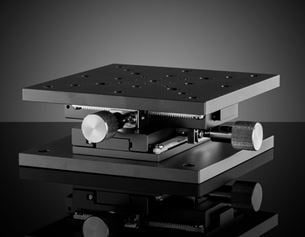

Crossed-Roller Bearing Linear Translation Stages (Standard-Top Model)

Crossed-Roller Bearing Linear Translation Stages (Standard-Top Model)

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Four Sizes Ranging from 30 x 30mm to 125 x 125mm

- English and Metric Hole Patterns Available

- Micrometer and Lead Screw Drive Options

- Easily Configured into X-Y and X-Y-Z Configurations

Crossed-Roller Bearing Linear Translation Stages (Thru-Hole Model)

Crossed-Roller Bearing Linear Translation Stages (Thru-Hole Model)

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Four Sizes Ranging from 30 x 30mm to 125 x 125mm

- Thru-Hole Design for Optical Path Transmission

- English and Metric Hole Patterns Available

- Micrometer and Lead Screw Drive Options

Stainless Steel Extended Contact Ball Bearing Linear Translation Stages

Stainless Steel Extended Contact Ball Bearing Linear Translation Stages

- Stainless Steel Construction for up to 20kg Load Capacity

- Provides Excellent Temperature and Straight-Line Stability

- Compatible with all TECHSPEC Manual Stages

Vertical Translation Stages

Vertical Translation Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Mechanically Compatible with our TECHSPEC® Stages

- Fine Micrometer Movement

- Locking Screw on Stages

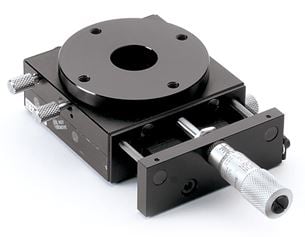

Rotary Stages

Rotary Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Low Profile Design

- Precision Micrometer Drive

- Slide-Fit Guide System

- 360° Coarse Rotation, ±5° Total Fine Rotation

- Mechanically Compatible to Other TECHSPEC® Stages

- Locking Screw on All Stages

- Class 100 (ISO 5) Clean Room Compatible

Tip-Tilt Stages

Tip-Tilt Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Metric and English Hole Pattern Versions Available

- Tilt Control in Two Axes (Kinematic Movement)

- Precision Micrometer Drive

- Mechanically Compatible to Other TECHSPEC® Stages

Goniometers

Goniometers

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Metric and English Hole Patterns Available

- Stackable for Two-Axis Rotation

- Mechanically Compatible with our TECHSPEC® Stages

X-Y Positioning Stages

X-Y Positioning Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Compatible with Our TECHSPEC® Manual Translation Stages for Additional Axis Alignment

- ±12.5mm or ±35mm Travel in Both X and Y for Quick X-Y Positioning

- Universal Bottom Plate for Both English and Metric Breadboard Mounting

High Load Capacity Dovetail Stages

High Load Capacity Dovetail Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Compact Overall Size for System Integration

- Brass Construction for High Stiffness and up to 15kg Load Capacity

- Compatible with All TECHSPEC® Stages

Metric Z-Axis Stages

Metric Z-Axis Stages

- Fine Micrometer Movement

- Available in Four Sizes

- Black Anodized Aluminum

- Locking Knob

Metric Rotary Stages

Metric Rotary Stages

- Precision Micrometer Drive and Manual Drive Options

- 360° Coarse Rotation

- Micrometer Drive Models Provide ±5° Fine Rotation

- Black Anodized Aluminum Construction

Metric Tilt Platform

Metric Tilt Platform

- Tilt Control in Two Axes (±2.5°)

- Multiple Tapped and C’bored Holes for Easy Mounting

- Black Anodized Aluminum

Metric Goniometers

Metric Goniometers

- Stackable for Two-Axis Rotation

- Durable Brass Construction

- Dovetail Design with Vernier Scale

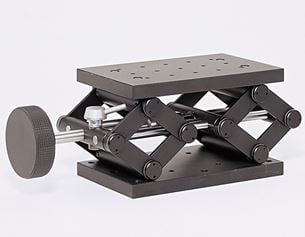

Metric Lab Jacks

Metric Lab Jacks

- Rugged, Black Anodized Aluminum Construction

- Fine Lead Screw for Precision Movement

- Large Adjustment Knob for Maximum Control

- Locking Knob to Secure Vertical Positioning

English Ball Bearing Translation Stages

English Ball Bearing Translation Stages

- Preloaded Ball Bearing Design for Low-Friction Linear Adjustment

- Solid-Top and Thru-Hole Versions

- English or Metric Micrometer Drive and Fine Screw Drive Available

- Stackable for 2-Axis or 3-Axis Movement

Metric Ball Bearing Translation Stages

Metric Ball Bearing Translation Stages

- Preloaded Ball Bearing Design for Low-Friction Linear Adjustment

- Solid-Top and Thru-Hole Versions

- English or Metric Micrometer Drive and Fine Screw Drive Available

- Stackable for 2-Axis or 3-Axis Movement

Positioning Stages with Digital Micrometers

Positioning Stages with Digital Micrometers

- 0.001mm Resolution Directly Readable Micrometer

- Readout in Inches or Millimeters

- Available with English or Metric Mounting Holes

Linear Motion Ball Bearing Slides

Linear Motion Ball Bearing Slides

- High Straight Line Accuracy

- Low Wear, Low Friction Sliding Motion

- Preloaded to Eliminate Wobble and Unwanted Play

Linear-Rotary Positioning Stage

Clearance

Linear-Rotary Positioning Stage

Clearance

- Compact Stage with Both Linear and Rotary Positioning

- Linear Adjustment with a Fine Resolution Micrometer

- Coarse or Fine Rotary Adjustment

Compact Rotary Stages

Compact Rotary Stages

- Low Wear, Low Friction Movement with Coarse or Fine Adjustment

- 2 or 2.62" Diameter Stages with Tapped Mounting Holes

- Calibrated Dial with 12 Minute Vernier for Accurate Read-Out

Heavy Load Capacity Rotary Positioning Stages

Heavy Load Capacity Rotary Positioning Stages

- Normal Load Capacity of 25lb (11.3kg) for heavy duty applications

- Precision Worm Gear Drive

- Compatible with Metric and English 5" Ball Stages

Micro Manual Rotary Stage

Micro Manual Rotary Stage

- Small Footprint

- 17 Degrees of Fine Adjustment

- 360 Degrees of Coarse Adjustment

Micro Manual Positioning Stages

Micro Manual Positioning Stages

- Two Micro Sizes Available

- Versions with Covered Rails

- Three Travel Selections

- X, XY, and XYZ Axis Models

Micro Manual Goniometers

Micro Manual Goniometers

- Small Footprint

- Zero-Backlash Drive System

- 25mm or 42mm Radius Versions Stackable to Create 2-Axis Version

Miniature Screw Drive Stages

Miniature Screw Drive Stages

- 8-32 or M4 Mounting Options Available

- Up to 19mm of Linear Travel

- Three-Start Screw Drive and Precision Lapped Surfaces for Smooth, Accurate Movement

Leadscrew Drive Stages

Leadscrew Drive Stages

- Locking Knobs for Secure Positioning

- 0.5mm Travel per Knob Rotation

- Available with up to 15mm Travel in X and Y with 12mm Travel in Z

Rack and Pinion Stages

Rack and Pinion Stages

- Aluminum Stage with Brass Rack and Pinion

- 20mm Travel per Knob Rotation

- Scale Features 1mm Increments with Locking Lever

- Basic Rack and Pinion Stages Also Available

Basic Rack and Pinion Stages

Basic Rack and Pinion Stages

- Multiple Configurations Available

- High Load Capacity

- Ideal for Applications Requiring Long Travel

- Additional Rack and Pinion Stages Available

X-Y-Z Positioning Movement

X-Y-Z Positioning Movement

- 50mm Diameter Optical Mount

- Includes Durable Mounting Base

- Helical Rack and Pinion Drive Mechanism

Long Travel Rack and Pinion Stages

Long Travel Rack and Pinion Stages

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Carriers Feature One or Two Knobs, with English or Metric Mounting Hole Patterns

- Available with Both English and Metric Track Lengths

- Preassembled Common Carrier and Track Combinations are Available

- Vernier Scales of 0.01” or 0.1mm Resolution

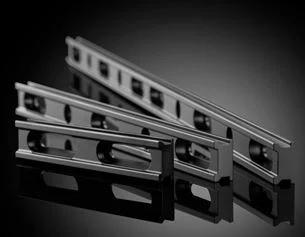

Dovetail Optical Rail Systems

Dovetail Optical Rail Systems

- Wide Range of Carrier Length and Mounting Hole Options Available

- Low Profile Design with Smooth Movement

- Increased Stability and <1mrad Straight Line Accuracy

Compact Optical Rail Systems

Compact Optical Rail Systems

- Rails and Carriers Available

- Mount on English and Metric Breadboards

- Low Profile Design

X-Y Positioning Tables

X-Y Positioning Tables

- Available Options of 70mm (±35mm)and 200mm(±100mm)Travel in Both X and Y

- Ball Bearing or Rack and Pinion Movements for Fast Adjustment

- Solid Top Designs

Accessories for Manual Stages and Slides | View All

Stage Adapter Plates and Accessories

Stage Adapter Plates and Accessories

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Compatible with 30mm, 40mm, 70mm and 125mm TECHSPEC® Crossed Roller Translation Stages

- Compatible with Rotary and Tip-Tilt TECHSPEC® Stages

- Used to Configure Stages into X-Y-Z Configurations

- Black Anodized Aluminum Construction

Drive Mechanisms

Drive Mechanisms

- Micrometer, Fine Screw, Digital and Differential Options Available

- Compatible with our Ball Bearing Stages

Zaber™ High Accuracy Linear Actuators

Zaber™ High Accuracy Linear Actuators

- Miniature, Robust Design

- Integrated Motor and Controller

- Controlled Manually or via RS-232 Serial Interface

- Available with Integrated, 250 Counts per Revolution (CPR) Motor Mounted Encoder

90° Angle Brackets

90° Angle Brackets

- Metric, English and Common Slotted Versions

- Standard ¼-20 or M6 x 1.0 Holes/Slots or AllSlots

- Large and Small Sizes

- Black Anodized Aluminum Construction

Top Plates for Ball Bearing Stages and Slides

Top Plates for Ball Bearing Stages and Slides

- Mounts English/Metric Post or Post Holders to Translation Stages

- Center ¼-20, M6 x 1.0 or M16 x 1.0 Threaded Hole

- Black Anodized Aluminum Construction

Adapter Plates for Ball Bearing Stages and Slides

Adapter Plates for Ball Bearing Stages and Slides

- Designed for Our Linear Positing Stages and Slides

- Centered ¼-20 Hole Enables Use with Posts and Post Holders

Z-Axis Brackets for Ball Bearing Stages

Z-Axis Brackets for Ball Bearing Stages

- Combine Ball Bearing Stages into 3 Axis Positioning Systems

- Designs for 1.25, 1.75, 2.62, and 5" Stages

- Aluminum Construction with Black Anodized Finish

Metric/English and English/Metric Adapter Plates

Metric/English and English/Metric Adapter Plates

- Connects Metric/English Components to English/Metric Breadboards

- Standard ¼-20 or M6 x 1.0 Holes and Slots

- Center C’bore Can Be Used for ¼ or M6 S.H.C.S.

- Large and Small Sizes

- Black Anodized Aluminum Construction

Ball-Point Hex Driver Sets

Ball-Point Hex Driver Sets

- English and Metric Driver Sets

- Up to 25° Angled Entry into Fasteners

- Ideal for use with the TECHSPEC® Cage System

Socket Head Cap Screws

Socket Head Cap Screws

- Ideal for Use with Our English Sized Positioning Equipment

- A Broad Selection of Sizes Available

- 50 Pieces per Package

- Socket Head Cap Screw Kits Available

- Allen Wrenches Also Available

Socket Head Cap Screw Kits

Socket Head Cap Screw Kits

- English and Metric Kits Available

- Comes with Storage Case

- Comes with Most Popular Sizes and Lengths

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act