Large Parabolic Reflectors

Large Parabolic Reflectors

- Ideal for Light Collection Applications

- Features Center Hole and Mounting Rim

- 12", 18", 24" Diameters Offered

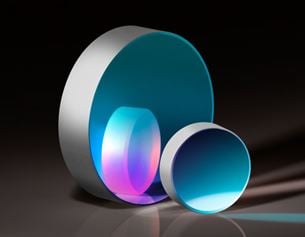

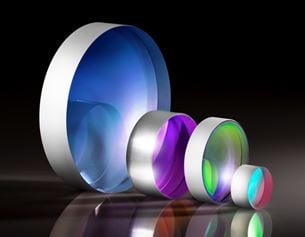

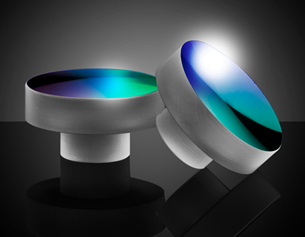

λ/8 Precision Spherical Mirrors

λ/8 Precision Spherical Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Multispectral Focusing Applications

- Variety of Coating Options Offered

- Multiple Sizes Available

- λ/4 Spherical Mirrors Also Available

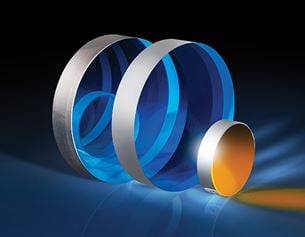

Precision Parabolic Mirrors

Precision Parabolic Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- λ/8 Surface Accuracy

- Wide Range of Sizes up to 412.8mm Diameter

- Variety of Coating Options Offered

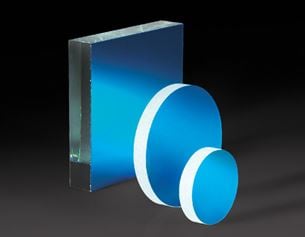

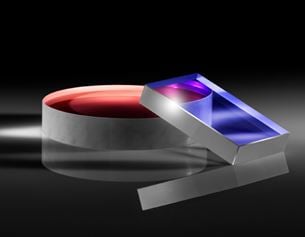

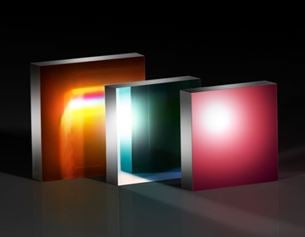

Precision Optical Flat Mirrors

Precision Optical Flat Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Fused Silica and ZERODUR® Substrates

- λ/10 and λ/20 Surface Flatness

- Variety of Coating Options Offered

λ/8 Precision Elliptical Flat Mirrors

λ/8 Precision Elliptical Flat Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Circular Profile When Oriented at 45°

- Ideal for Redirecting Light

- Multiple Sizes and Coatings Offered

Visible Laser Diode Mirrors

Visible Laser Diode Mirrors

- Over 95% Reflectance of Visible Laser Diode Light

- Ideal for Multiple Reflection Systems

- Coating Optimized for 633nm at 45° AOI

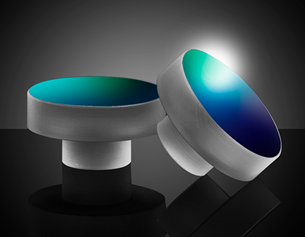

λ/4 Precision Spherical Mirrors

λ/4 Precision Spherical Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Multispectral Focusing Applications

- Variety of Coating Options Offered

- Multiple Sizes Available

- λ/8 Precision Spherical Mirrors Also Available

First Surface Mirrors

First Surface Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Wide Variety of Shapes and Sizes Available

- Enhanced Aluminum, Protected Gold, and Protected Silver Coatings for high reflectivity from 450-10000nm

- Contact Us for Custom Sizes

Single Surface Optical Flats

Single Surface Optical Flats

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Sizes Ranging from ½" Diameter to 14" Diameter

- Each λ/20 Flat 76.2mm and Larger Includes a Certificate of Calibration

- Available with Standard Metallic Mirror Coatings: λ/10 and λ/20 Mirrors

Concave Spherical Mirrors

Concave Spherical Mirrors

- Ideal for Focusing Light

- Aluminum and Gold Coating Options

- Available in Sizes Ranging from 9 - 50mm

λ/4 First Surface Mirrors

λ/4 First Surface Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Available in a Wide Range of Sizes and Shapes

- Precision Metallic Mirror Coatings

- Contact Us for Custom Sizes

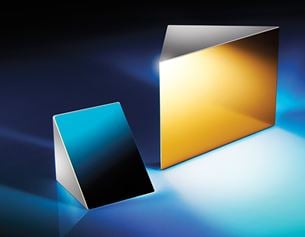

Right Angle Mirrors

Right Angle Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Reflects Light at 90°

- Ideal for System Alignment

- Enhanced Aluminum, Protected Gold, and Protected Silver Coatings

Precision Broadband Laser Mirrors

Precision Broadband Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Tunable Lasers and Reflecting Multiple Laser Sources

- High Reflectivity from 0 - 45° for All Polarization States

- Variety of Coating Options Available

4-6λ First Surface Mirrors

4-6λ First Surface Mirrors

- Wide Variety of Shapes and Sizes Available

- >85% Reflection of Visible Light

- Contact Us for Custom Sizes

90° Specialty Mirrors

90° Specialty Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Splits Input Image Into Two Paths Separated by 180°

- Variety of Sizes and Broadband Coatings Available

- Additional Right Angle Prism Options Available

Diode Laser Line Mirrors

Diode Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Reflectivity at Design Wavelengths

- Excellent Broadband Performance for Range of Wavelengths

- Designed for Common Diode Lasers

λ/4 Spherical Mirrors

λ/4 Spherical Mirrors

- Aluminum Coating

- Ideal for UV, Visible, and IR Applications

- Multiple Diameter and f/# Combinations Available

Excimer Laser Line Mirrors

Excimer Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- High Damage Threshold of up to 1.5 J/cm2

- Low Loss Dielectric Coatings

- Designed for 193nm and 248nm Lasers

Precision Ultraviolet Mirrors

Precision Ultraviolet Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- 120nm and 190nm Design Wavelengths

- Average Reflectivity >85% Across Specified Range

- Enhanced Metallic Coatings for Broadband Reflectivity through the Visible Region

High Performance Off-Axis Parabolic Mirrors

High Performance Off-Axis Parabolic Mirrors

- High Quality Glass Substrate

- λ/4 or λ/2 Surface Accuracy

- Ideal for UV and Visible Applications

λ/10 First Surface Mirrors

λ/10 First Surface Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Precision Fused Silica Substrate

- Variety of Sizes and Coating Options Available

- Low Coefficient of Thermal Expansion

Convex Spherical Mirrors

Convex Spherical Mirrors

- Variety of Diameters and Focal Lengths Available

- Enhanced Aluminum and Protected Gold Coatings

- Ideal for Imaging Systems

Broadband Dielectric λ/10 Mirrors

Broadband Dielectric λ/10 Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Enhanced Reflectivity and LIDT over Metallic Coatings

- Average Reflectivity >99% Over Broad UV, Visible, and NIR Wavelengths

- Designed for all Polarization States from 0 – 45° AOI

Broadband Dielectric Coated Right Angle Mirrors

Broadband Dielectric Coated Right Angle Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Greater Than 98% Reflection Over Broad Wavelength Ranges

- High Reflectivity for all Polarization States

- Reflect Light at 90°

- Standard Metal Coated Right Angle Mirrors Also Availble

Convex Mirrors

Convex Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Precision Polished Surface

- λ/2 Surface Accuracy

- Variety of Coating Options Offered

λ/20 First Surface Mirrors

λ/20 First Surface Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Precision Fused Silica Substrate

- 20-10 Surface Quality

- Low Coefficient of Thermal Expansion

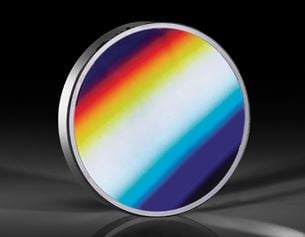

Richardson Gratings™ High Precision Plane Ruled Reflective Diffraction Gratings

New

Richardson Gratings™ High Precision Plane Ruled Reflective Diffraction Gratings

New

- Excellent Efficiency at Blaze Wavelength and Blaze Angle

- Superior Dimensional Tolerances

- Ideally Suited for Spectroscopic Applications

- Custom Sizes Available

Extreme Ultraviolet (EUV) Flat Mirrors

Extreme Ultraviolet (EUV) Flat Mirrors

- Maximum Achievable Reflection at 13.5nm

- Designed for EUV Beam Steering and Harmonic Separation

- 5° and 45° AOI Versions Available

Low Cost Laser Line Mirrors

New

Low Cost Laser Line Mirrors

New

- >97% Reflectivity at Design Wavelength

- Up to λ/10 Surface Accuracy

- Excellent Cost to Performance Ratio

- Designs for Nd:YAG, Yb:YAG, and Diode Lasers

2μm Laser Line Mirrors

2μm Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Laser Damage Threshold >10 J/cm2 @ 2µm, 10ns, 10Hz

- Designed for Holmium and Thulium Laser Sources

- λ/7 Surface Accuracy

ZERODUR® λ/10 First Surface Mirrors

ZERODUR® λ/10 First Surface Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Precision ZERODUR® Substrates

- λ/10 Flatness

- Low Coefficient of Thermal Expansion

Concave Laser Line Mirrors

Concave Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Focusing Laser Light

- >99.8% Reflectivity at Center Wavelength

- High Thermal Stability Fused Silica Substrates

Aluminum Off-Axis Parabolic Mirrors

Aluminum Off-Axis Parabolic Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Aluminum Coatings for UV, Visible, and NIR Applications

- Range of Surface Roughness, Including 50Å and 100Å

- 15°, 30°, 45°, 60°, or 90° Offset Angle Options

- Gold and Silver Coated Off-Axis Parabolic Mirrors Also Available

Gold Off-Axis Parabolic Mirrors

Gold Off-Axis Parabolic Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Bare or Protected Gold Coating for NIR and IR Applications

- 50Å and 100Å Surface Roughness Options

- 15°, 30°, 45°, 60°, or 90° Offset Angles

- Aluminum and Silver Coated Mirrors Also Available

UltraFast Innovations (UFI) 2μm Highly-Dispersive Broadband Ultrafast Mirrors

UltraFast Innovations (UFI) 2μm Highly-Dispersive Broadband Ultrafast Mirrors

- Reflectivity >99.9% Between 2000 - 2200nm

- GDD of -1000fs2 @ 5° AOI

- Ideal for <100fs Pulse Compression of Thulium and Holmium Lasers

- Broadband Ultrafast Chirped Coating

High Performance Low GDD Ultrafast Mirrors

High Performance Low GDD Ultrafast Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Designed with High Reflectivity for Ultrafast Beam Steering

- Ion-Beam Sputtered Coating for Low Scatter and Absorption

- GDD as Low as 0±20fs2 at Design Wavelength Range

Uncoated Concave Laser Mirrors

Uncoated Concave Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- High Precision Fused Silica Mirror Substrates

- Large Selection of Diameters and Focal Lengths

- Custom Coating Options Available

Laser Mirror Substrates

Laser Mirror Substrates

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- λ/10 Surface Flatness and 10-5 Surface Quality

- High Quality Fused Silica Substrates

- Imperial Sizes with Circular or Rectangular Geometries

- Window Substrates Also Available

UltraFast Innovations (UFI) 780 and 800nm Highly-Dispersive Ultrafast Mirrors

UltraFast Innovations (UFI) 780 and 800nm Highly-Dispersive Ultrafast Mirrors

- Reflection >99.8% (P-polarization) at 720 – 840nm or 780 – 830nm

- Low Group Delay Dispersion at 5° or 20° AOIs

- Ideal for Pulse Compression of Ti:sapphire Ultrafast Lasers

- Low GDD Mirrors Also Available

UltraFast Innovations (UFI) 1030nm Highly-Dispersive Broadband Ultrafast Mirrors

UltraFast Innovations (UFI) 1030nm Highly-Dispersive Broadband Ultrafast Mirrors

- Negative GDD of -200 fs2 at 5° AOI

- >99.8% Reflection (p-polarization) between 950 - 1120nm

- Designed for Pulse Compression of Yb:doped Fiber Lasers

- Broadband Ultrafast Chirped Coating

UltraFast Innovations (UFI) 1030nm Highly-Dispersive Ultrafast Mirrors

UltraFast Innovations (UFI) 1030nm Highly-Dispersive Ultrafast Mirrors

- Highly Negative GDD up to -1000 fs2 at 7° AOI

- >99.8% Minimum Reflection across 60nm Bandwidth

- Ideal for Dispersion Compensation of Yb:doped Fiber Lasers

- Ultrafast Chirped Coating

UltraFast Innovations (UFI) 45° AOI Ultrafast Chirped Mirrors

UltraFast Innovations (UFI) 45° AOI Ultrafast Chirped Mirrors

- High Reflectivity and Negative Group Delay Dispersion (GDD)

- Ideal for Dispersion Compensation and Beam Compression @ 45° AOI

- Designs for Femtosecond Lasers, Including Ti:sapphire

Nd:YAG Laser Line Mirrors

Nd:YAG Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Up to 99.9% Reflectivity at Nd:YAG Harmonic Frequencies

- High Laser Induced Damage Threshold Specifications

- 10-5 Surface Quality for Reduced Scatter in Sensitive Laser Applications

- TECHSPEC® Laser Mirror Substrates and TECHSPEC® Yb:YAG Laser Line Mirrors Also Available

Yb:YAG Laser Line Mirrors

Yb:YAG Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Reflectivity at Yb:YAG Harmonic Frequencies

- Guaranteed High Laser Damage Thresholds

- 10-5 Surface Quality for Reduced Scatter in Laser Applications

- TECHSPEC® Laser Mirror Substrates and TECHSPEC® Nd:YAG Laser Line Mirrors Also Available

Ultrafast-Enhanced Silver Laser Mirrors

Ultrafast-Enhanced Silver Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Reflectivity >99% at 600 – 1000nm or 800 – 1150nm

- Low Group Delay Dispersion as Low as 0 ±20fs2

- Ideal for Ti:sapphire and Yb:doped Lasers

- Standard Imperial Sizes Available

- TECHSPEC® Ultrafast-Enhanced Silver Concave Laser Mirrors Available

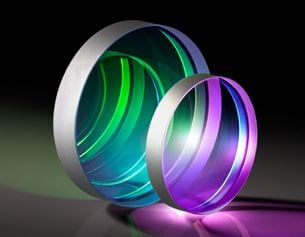

Ultrafast-Enhanced Silver Concave Laser Mirrors

Ultrafast-Enhanced Silver Concave Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Focusing Ti:sapphire and Yb:doped Laser Pulses

- Reflectivity >99% at 600 – 1000nm or 800 – 1150nm

- Low Group Delay Dispersion as Low as 0 ±20fs2

- Effective Focal Lengths from 25 to 500mm

- TECHSPEC® Ultrafast-Enhanced Silver Laser Mirrors Available

ZEISS Concave Diffraction Gratings

ZEISS Concave Diffraction Gratings

- High Grating Efficiency and Low Stray Light

- Holographically Produced to Minimize Aberrations

- Rowland Circle or Polychromator Mounting Configurations

UltraFast Innovations (UFI) Ultra-Broadband Complementary Chirped Mirror Pairs

UltraFast Innovations (UFI) Ultra-Broadband Complementary Chirped Mirror Pairs

- Ideal for Chirped-Pulse Amplifier Systems and Ultra-Broadband Laser Oscillators

- Ultra-Broadband Design Supports Dispersion Compensation

- Negative GDD as Low as -60fs2 and High Reflectivity (>99%) at 600 – 950nm or 650 – 1350nm

Nd:YAG Laser Output Couplers

Nd:YAG Laser Output Couplers

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Designs for 532nm and 1064nm Nd:YAG Lasers

- 80% Reflectivity at Nd:YAG DWL

- UV Fused Silica Substrates

Rhodium Coated First Surface Mirrors

Rhodium Coated First Surface Mirrors

- Corrosion and Extreme Abrasion Resistant Rhodium Coating

- High Reflectivity in the VIS and IR

- Ideal for Orthodontic Applications

UltraFast Innovations (UFI) High-Power Low-Loss Laser Mirrors

UltraFast Innovations (UFI) High-Power Low-Loss Laser Mirrors

- >99.99% Reflectivity at 1030nm and 1064nm

- Laser Damage Threshold of 50 J/cm2 at 1064nm, 100Hz, 8ns

- Universal Designs for Nanosecond, Picosecond, and Femtosecond Laser Pulses

- Custom Options are Available up to 200mm Diameter

Richardson Gratings™ Echelle Reflective Diffraction Gratings

Richardson Gratings™ Echelle Reflective Diffraction Gratings

- Highest Resolving Power and Dispersion

- Low Groove Density for Use in Higher Orders

- Groove Spacing Tolerance <0.05%

- Custom Sizes Available

Richardson Gratings™ High Precision Reflective Holographic Diffraction Gratings

Richardson Gratings™ High Precision Reflective Holographic Diffraction Gratings

- High Diffraction Efficiency

- Reduced Stray Light and More Accurate Periodicity than Ruled Gratings

- Wavelength Options from UV to NIR Regions Available

- Custom Sizes Available

Richardson Gratings™ High Precision Plane Reflective Gold Diffraction Gratings

Richardson Gratings™ High Precision Plane Reflective Gold Diffraction Gratings

- Optimized for use from 350-800nm (500nm) or 700-1600nm (1000nm)

- Available in standard sizes 12.7 x 12.7, 25 x 25 and 30 x 30mm

- Groove Spacing Tolerance <0.05%

- Custom Sizes Available

Laser Line Coated Off-Axis Parabolic (OAP) Mirrors

Laser Line Coated Off-Axis Parabolic (OAP) Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Dielectric Laser Line Coatings for 532 and 1064nm

- Ideal for Collimating or Focusing Nd:YAG Laser Light

- >99.5% Reflectivity at Nd:YAG Design Wavelengths

- Metallic Coated Off-Axis Parabolic Mirrors Also Available

Ultrafast-Enhanced Silver Coated Off-Axis Parabolic (OAP) Mirrors

Ultrafast-Enhanced Silver Coated Off-Axis Parabolic (OAP) Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ultrafast-Enhanced Silver Coating for Ti:sapphire and Yb:doped Lasers

- Low Group Delay Dispersion

- <50Å RMS Surface Roughness to Minimize Scatter

Nd:YAG Laser Replacement Parts

Nd:YAG Laser Replacement Parts

- Output Couplers, Laser Line Mirrors, and Nd:YAG Rods

- 80% or 90% Reflectivity @ 1064nm Output Couplers

- 0.6% Nd Dopant Nd:YAG Rods

- Large Selection of Complementary Nd:YAG Laser Optics Available

Dual Band Low GDD Ultrafast Mirrors

Dual Band Low GDD Ultrafast Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- High Reflectivity & Low Group Delay Dispersion (GDD) for Ultrafast Beam Steering

- Ion-Beam Sputtered (IBS) Coatings Minimize Scatter and Absorption Losses

- Near-Zero GDD for Both the First and Second Harmonics of Ti:sapphire and Yb-doped Lasers

Stemmed Laser Mirrors

Stemmed Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Stemmed Design Reduces Stress on Mirror Surface when Mounted by Stem

- >99% Reflectivity at Standard Laser Wavelengths

- 10-5 Surface Quality for Reduced Scatter in Sensitive Laser Applications

- TECHSPEC® Broadband Dielectric and Metallic Coated Stemmed Mirrors Also Available

Broadband Dielectric Stemmed Mirrors

Broadband Dielectric Stemmed Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Stemmed Design Reduces Stress on Mirror Surface when Mounted by Stem

- >99% Average Reflectivity Over Broad Wavelength Ranges

- 20-10 Surface Quality and 0 - 45° Angle of Incidence

- TECHSPEC® Laser and Metallic Coated Stemmed Mirrors Also Available

Metallic Coated Stemmed Mirrors

Metallic Coated Stemmed Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Stemmed Design Reduces Stress on Mirror Surface when Mounted by Stem

- Durable Fused Silica Construction for Low Coefficient of Thermal Expansion

- Enhanced Aluminum, Protected Gold, and Protected Silver Coatings

- TECHSPEC® Laser and Broadband Dielectric Stemmed Mirrors Also Available

Schwarz Mirrors

Clearance

Schwarz Mirrors

Clearance

- Engineered Highly- Absorptive Fused Silica Substrate

- Optical Density > 7.0 in Visible Spectrum

- >98% Visible Reflectivity with No Residual Transmission

- Damage Threshold > 0.5J/cm2, 20ns, 20Hz @ 532nm

- Designed for all Polarization States from 0 - 45° AOI

Dual Band Laser Line Mirrors

Dual Band Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99% Reflectivity at Design Wavelengths

- 10-5 Surface Quality for Sensitive Laser Applications

- 532/1064nm, 635-670/1064nm, or 800/1030nm Wavelength Bands

- TECHSPEC® Nd:YAG Laser Line Mirrors Also Available

Ultra-High Reflectivity (UHR) Broadband Dielectric Mirrors

Clearance

Ultra-High Reflectivity (UHR) Broadband Dielectric Mirrors

Clearance

- >99.8% Reflectivity over Broad Visible or NIR Wavelength Ranges

- 10-5 Surface Quality for Reduced Scatter in Sensitive Laser Applications

- λ/10 Surface Flatness

λ/20 Fused Silica Right Angle Mirrors

λ/20 Fused Silica Right Angle Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Precision Fused Silica Substrates for Increased Thermal Stability

- Ideal for System Alignment

- Enhanced Aluminum, Protected Gold, and Protected Silver Coatings Available

ISP Optics Gold Coated Mirrors

Clearance

ISP Optics Gold Coated Mirrors

Clearance

- Pyrex® Mirror Substrates

- Protected Gold Coating

- Ideal for LWIR Applications

920nm Laser Line Mirrors

920nm Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Absolute Reflectivity at 920nm

- 99.5% Average Reflectivity in the 905 - 935nm Range

- High Laser Damage Threshold

- Wide Range of Laser Line Mirrors Options Available

1310nm Laser Line Mirrors

1310nm Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Reflectivity at 1310nm

- 99.5% Average Reflectivity in the 1295 - 1325nm Range

- High Laser Damage Threshold

- Wide Range of Laser Line Mirrors Options Available

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act